The Gilding Restoration Process: An Inside Look

Gilding is a beautiful decorative technique which consists of applying a thin layer of metal called leaf to a surface in order to give the appearance of solid gold, silver, or any other desired metal. When performed well, gilding has the power to signify beauty, richness, greatness, and to elevate minds and hearts to ponder nobility or even divinity. Consequently, the gilding restoration process is a noble art which will ultimately be worth the effort and prove highly rewarding in the end.

Process

The process of historic gilding restoration is similar to that of gilding a new surface with the exception of adding a prior step of stripping the old leaf as well as understanding the history of the project’s original design.

1) Understand and Value Gilding History

Historic restoration is the process of re-verting a piece of work back to its original design and beauty. In order to accomplish such a task, the artist must not only be skilled in the trade at hand, but also understand and value the historic design in order to properly replicate it. A historic building assessment is an investigation including historic and scientific research which helps determine the original state of the building as well as its architectural elements such as gilding.

2) Strip the Old

Stripping the old metal leaf before applying the new is possibly the most important step when gilding is perform on the exterior of a building. This is worth repeating: you must strip off old coatings to the bare substrate prior to any gilding applications. It is vital that this step is executed properly in order for the surface to be in optimal condition to receive the new leaf. If there is any residue at all, the new leaf will not stick well and the whole project will have to be redone. The stripping process can be done in a number of ways, depending on specific conditions such as what material is underneath, how much of the previous leaf is left, how easily it comes off, etc. Often, mechanical techniques like sanding and scraping are coupled with chemical products to remove the old leaf carefully and efficiently.

3) Gild the New

Materials for the project should be chosen according to the information obtained in the first step and, once the surface is stripped, the 5-step gilding process (prepare/prime surface, apply adhesive, apply leaf, remove excess, and seal and finish) may commence.

Stripping of old metal leaf in process.

Materials

Basic materials needed for a gilding restoration project include stripping products and instruments, primer, size, gold leaf, and any additional tools needed.

Stripping Materials

Mechanical stripping tools include steel wool, Scotch-Brite pads, sand paper, electric sanders, media blasting (depending on substrate) and other scraping tools. Chemical products like stripping paint thinners are also often used. The stripping process should also include cleaning the surface with a solvent such as mineral spirits or xylene in order to remove any grease, dirt, dust, or any other contaminants.

Primer

Following the stripping process, the surface is often primed with a warm or cool color in order to give a uniform appearance to the end product. Direct-to-metal primers and extreme bond primers are generally good products to use. It is best to consult manufacturers for the products best suited for your particular substrate. They often will perform coating adhesion tests during the trial process in order to make the proper recommendation.

Size

The adhesive used to glue the gold leaf is called size and can be oil or water-based. Although interior projects can utilize either type, it is important to employ only oil-based size to all exterior projects since water-based size is subject to corrosion.

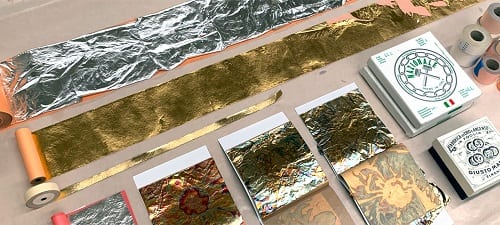

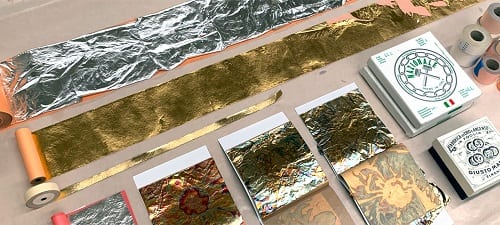

Metal Leaf

Gilding leaf comes in all types of metal- gold, silver, copper, aluminum, imitation leaf, and others. The most common is gold leaf which varies in weight and gold content. It is important to choose a gold leaf with a heavy enough weight and a high enough gold content for all exterior projects, since they must withstand rain, wind, snow, sleet, hail, and other corroding elements. The weight and content matters less for interior projects. Typically, interior gold leaf should be 22 karat at a weight of 15 to 18 grams per 1000 sheet of gold, whereas gold leaf used for exterior projects should be 23.75 karat at a weight of 21 to 23 grams per 1000 sheets. John Canning & Co. exclusively uses gold leaf of 23 grams for all exterior projects, most of which is manufactured in Italy and, secondarily, Germany. There are two types of leaf : loose leaf and transfer/patent leaf. Depending on the what is being gilded and whether indoor or outdoor the leaf form will vary. Loose leaf is mainly for indoor projects because the leaves are only held in place by pages of specialty paper they are between. Transfer leaf is adhered to a sheet of special transfer paper that gets applied to an object with a little pressure and is suitable for exterior and interior projects. Transfer leaf can come packaged in booklet or in roll leaf (long sheets of leaf that can be trimmed to various sizes and is typically used for applying leaf over large areas).

Other Useful Tools

Other useful tools include sable hair brushes, cotton cloths, aprons, buckets, scaffolding, etc. The softer the brush the less likely one will scratch the gilding. Therefore, we recommend sable hair brushes in flat or round form. A gilders tip may be used when applying a loose leaf metal.

Gilding in process. Metal leaf being applied to size.

Cost

The factors that play a role in determining the cost of a certain gilding project depend on a number of unique circumstances. For this reason, it is hard to state what a typical cost might be. Some basic cost factors include the following:

- The type of metal leaf to be used (whether gold, silver, or some other metal).

- The size, complexity, and scope of the project.

- Required access (for example, whether the surface is located on a wall vs. a ceiling vs. an exterior surface like a dome).

- Whether the underlying structure must be repaired, stabilized, or restored.

- Special materials costs.

Timeline

Similarly, the time taken to complete a gilding restoration project varies according to most of the same circumstances, particularly the size of the project and the number workers on the job. To get an accurate estimate of a specific job, it is best to consult an experienced restoration contractor. If you have a project you would like to discuss, please contact us.